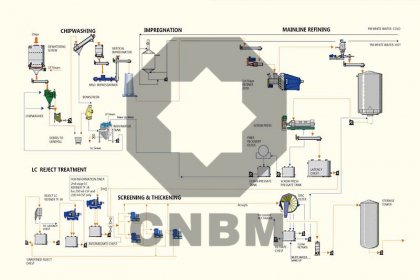

CNBM helps you to build complete paper pulping system according to your need and budget. We can plan and set AMPM production line, continuous cooking system, replacement digester system, super batch cooking production system, washing & bleaching system and other paper pulping line if you asked.

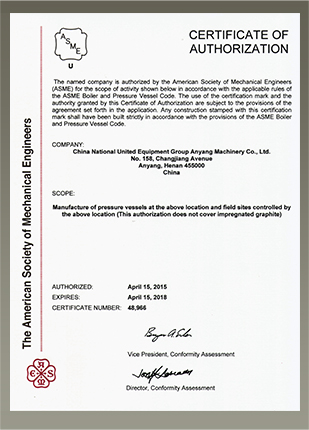

CNBM offers you the world class paper pulping machines including pulp cooking digester, vacuum drum washer, single screw press, twin roll press, disc filter, gravity disc thickener, blowing tank, heat exchanger, and replacement tank. Our products are all certificated with CE and ISO:9001, please purchase at ease.

Besides the machines and systems we can planning and engineering, we provide auxiliary products as well. We customize alkali recovery system, bleaching tower, desander, Johnson screen, pressure knotter, pressure screen pulp board machine, pulp diffusion tube and regulating device. We are ready for your orders.

Expert in manufacture pulp and paper-making machinery

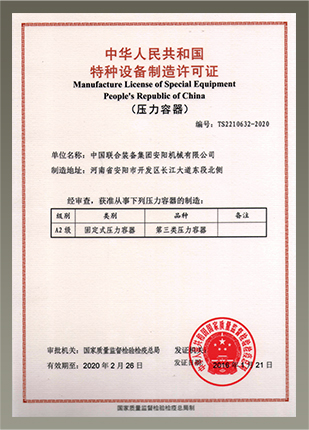

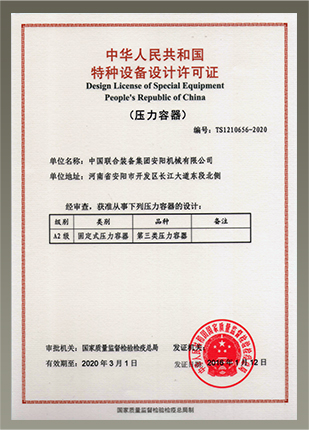

CNBM aka Anyang Machinery Co., Ltd., was founded in 1968. It is one big state owned enterprise which affiliated to China National United Equipment Group corp. It is located in Anyang, Henan Province, China, a famous tourist city with more than 3000 years history. CNBM is specialized in manufacture pulp and paper-making machinery. Now, the CNBM factory covers more than 130000m2 and its yearly production value can reach USD 100 million. CNBM has won reputation among both domestic and overseas. Our high-quality digester, disc filter, vacuum drum washer and other machines and systems have been exported to Indonesia, Vietnam, Pakistan, Malaysia and more countries.

In HongKong, Lee & Man Paper Manufacturing Limited

View projects

According to the actual needs of the clients, we can make special plans for your production lines. We offer paper pulping machines and systems in different specifications and models to meet your requirement and provide customers training technical personnel to help your team to master certain skills. All the services are free.

In the sales process, we track the production process to ensure the quality and shorten the production cycle. For the clients’ convenience, we send senior technical personnel for free to help with the construction. What’s more, after the construction, we can assign our professional staff to the scene to guide the clients and their teams.

CNBM has got the support of advanced paper and pulp technology. Thus, besides the routine services we mentioned above, we can also offer strategic planning, technical support, general contracting service as well. And we help with upgrading and rebuilt of the production line, applications for energy and water saving etc.

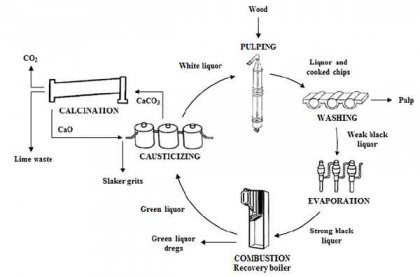

Chemical Recovery in Pulp And Paper Industry

Chemical Recovery in Pulp And Paper Industry

In paper pulping process, chemical recovery is an important process that maximise steam and power production capacity, reduce recirculating chemical dead loads, and minimise chemical losses....

Paper Pulping Process Introduction

Paper Pulping Process Introduction

Paper pulping process can be divided into chemical pulping method and mechanical pulping method. For different paper quality requirements, chemical pulping and mechanical pulping are needed....

Apmp Pulping Technology And Its Development Potential In The World Market

Apmp Pulping Technology And Its Development Potential In The World Market

APMP has been widely used in developed countries as its main pulping technology and pulping equipment. The development potential of APMP in the world market is huge. Welcome friends from all over the world to contact us!...

Leave messages for quotations and solutions. The average response time is up to 24 hours. Your privacy is protected. Check privacy policy here.