continuous cooking system

- For large-scale cooking equipment, the capital investment and operation cost of continuous cooking equipment are low.

- The quantity of pulp in unit pot is high, and the area is relatively small.

- Energy consumption is low, and steam and electricity consumption is balanced, avoiding peak load.

Chemical pulping refers to the whole process of dissociating cellulose into the desired pulp. It means put fiber raw materials in the cooking equipment, together with the appropriate amount of chemicals (cooking medicine) under the appropriate pressure, and within a certain period of time to keep the pressure, most of the fiber raw material lignin could dissolved in the solution. Chemical pulping equipment is generally divided into intermittent and continuous types according to the operation process. We mainly talk about the continuous cooking system in this article.

What is a continuous cooking system

Continuous cooking system refers to the chemical pulping equipment for pulp with continuous cooking. It realizes the continuous process of feeding, heating, cooking, heat preservation and discharging of batch cooking equipment at the same time. The continuous cooking system of paper pulp is of great significance to the development of paper pulping technology and to the improvement of working conditions and productivity of paper making industry. Its emergence is a breakthrough in the development of cooking equipment, which promotes the rapid development of pulping industry. Since the first continuous cooking system for chemical pulp was put into operation, the application and research of continuous cooking technology have developed rapidly. Up to now, most the total pulp output in the world is produced by continuous cooking system.

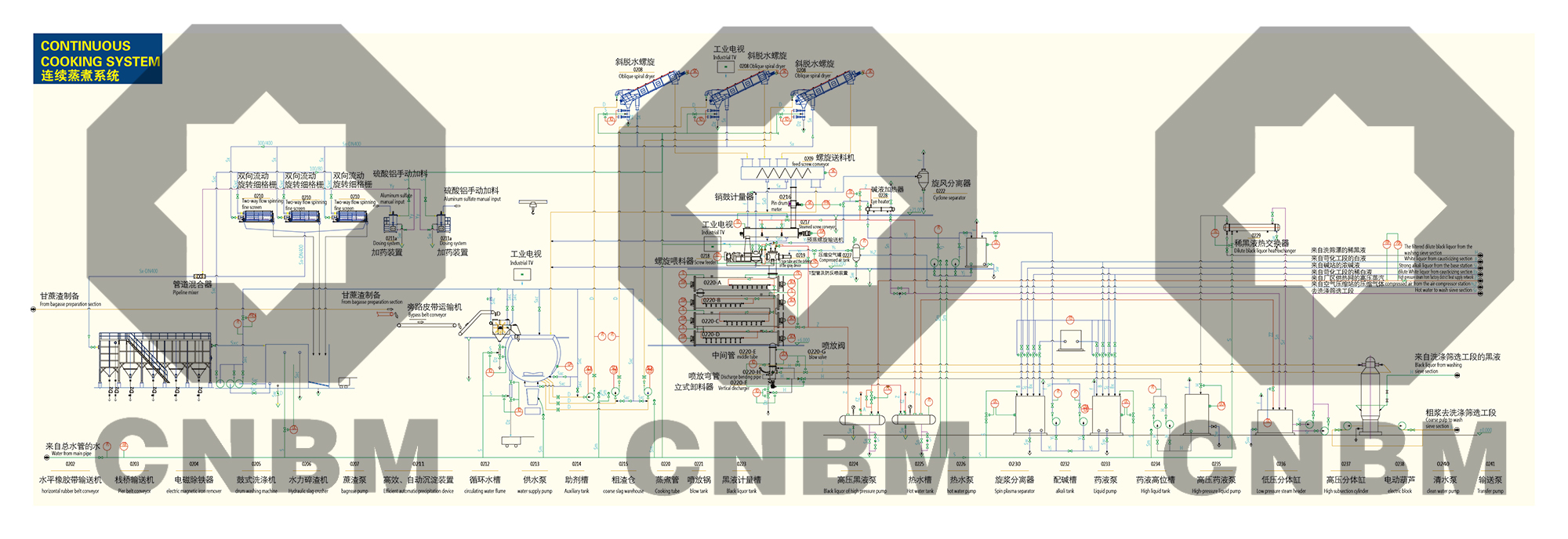

Continuous cooking system we offer

Continuous cooking system can be divided into tower type (or vertical) continuous steamer according to the main cooking equipment, also called Camille (Kamyr) continuous steamer, and Pandia horizontal tube type and oblique tube continuous steamer. The tower can be divided into single tower type and double tower type, horizontal tube type can be divided into one, two, three tube type, inclined tube type can be divided into single inclined tube and double inclined tube type. Among them, the tower type continuous cooker is suitable for large and medium wood pulp plants, and is the most widely used in the world. It has been used in pulp and paper industry in both home and abroad. At present, the equipment provided by CNBM for customers at home and abroad is mainly horizontal tube type continuous cooking system. Therefore, here we briefly introduce the horizontal tube type continuous cooking system.

The transverse-tube continuous cooking systems abroad include Pandia, Defibrator and Grenco among which Pandia is the most commonly used type. Pandia continuous cooking system was developed by Black-Crowson Company in 1948 and named as Pandia continuous Cooking system. It is mainly used to produce semi-chemical pulp of broad-leaved neutral sulfite process. Because it is suitable for steaming of straw fibers, this equipment is widely used in large bagasse and straw pulp mills abroad.

The production capacity of single equipment is smaller than that of Camille cooker. At present, the largest practical use abroad is 300 t/d. The first 10 t/d horizontal tube continuous cooking system and the first 50 t/d horizontal tube continuous cooking system in China were put into operation in the early 1970s. Now, the horizontal tube type continuous cooking system has completely realized the localization. CNBM horizontal tube continuous cooking system products features mature technology, reliable quality, have won good reputation in domestic and foreign.

continuous cooking system working principle

There are three main types of continuous cooking process of horizontal pipe in the world.

- Suitable for materials with small density, high compressibility, easy to form material plug and strong absorbability of medicine liquid, such as rice and wheat grass, bagasse and Reed, etc. The system adopts horizontal spiral presteam, high compression ratio screw feeder and spray mixing method to apply medicine. This called soft non-wood fiber raw materials of continuous cooking.

- The liquid is prestewed in the vertical movable bottom bin with small compression ratio screw feeder and pressure impregnator. It is more suitable for bamboo chips, cotton stalks and wood chips with poor absorbability than screw feeder and pressure impregnator in small compression, which is called the continuous steaming machine of hard non-wood fiber raw material.

- Process of continuous Cooking with double Spray-out horizontal tube. This process is a special technology of Peadco Company, which is suitable for cooking bagasse, wheat straw and bamboo silk.

Key equipment of continuous cooking system

-

Spiral feeder

The helical feeder is the most important equipment of the horizontal tube continuous cooker, which is mainly composed of feeding screw, conical shell, plug pipe and transmission device. It determines the stability of the whole system. Its function is to compress the sheet into a plug while feeding the system to seal the steam pressure backwash in the cooking pipe. The physical properties of different raw materials, such as shape, size, internal friction coefficient, fluidity and so on, have great influence on the design of screw feeder. -

Cooking tube

The cooking tube is the main component of the continuous cooker. After the material sheet is treated before, continue to be stirred and mixed together with the medicine liquid in the cooking pipe, and mix evenly with the medicine solution. The temperature is heated directly to steam for a certain time, until the pulping is finished and pushed to the discharger. -

Dispensing mechanism

A very important condition for the normal operation of a continuous cooker is the uniform, continuous, and quantitative feeding. The choice of metering instrument has a great influence on the whole system. If the selection is not proper, it will not only affect the accuracy of measurement, but also affect the uniform and continuous feeding, and induce the screw feeder to block and reverse spray. The double pin drum, double wave wheel or double helical metering device are mostly used for non-wood fiber raw materials. They are all equipped with variable speed transmission, which can be measured and controlled by adjusting their rotational speed.

>The horizontal tube continuous digester is a multi machine combined continuous operation system composed of a series of conveying machinery. All parts must be coordinated according to predetermined requirements, otherwise production is difficult to work smoothly. Equipped with advanced and reliable instrument control is an effective guarantee to ensure coordinated operation.

>The horizontal tube continuous digester is a multi machine combined continuous operation system composed of a series of conveying machinery. All parts must be coordinated according to predetermined requirements, otherwise production is difficult to work smoothly. Equipped with advanced and reliable instrument control is an effective guarantee to ensure coordinated operation.

Continuous cooking system advantages

It is generally believed that the advantages of the continuous cooking system lie in the following aspects:

- For large-scale cooking equipment, the capital investment and operation cost of continuous cooking equipment are low.

- The quantity of pulp in unit pot is high, and the area is relatively small.

- Energy consumption is low, and steam and electricity consumption is balanced, avoiding peak load.

- Less manpower is consumed. However, for highly automated intermittent cooking equipment, the two do not differ significantly.

- Cooking uniformity is better, even when large pieces of wood are produced, the residue is less.

Leave messages for quotations and solutions. The average response time is up to 24 hours. Your privacy is protected. Check privacy policy here.