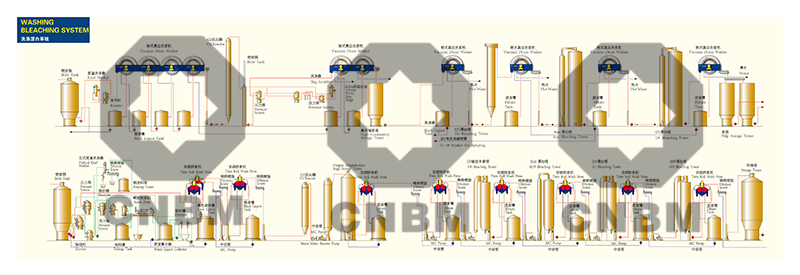

Washing & Bleaching System

- ZNH multi disk vacuum filter

- Vacuum washing machine series

- Drop washing machine series

- Gravity type circular mesh thickener

- H2627 black liquid filter

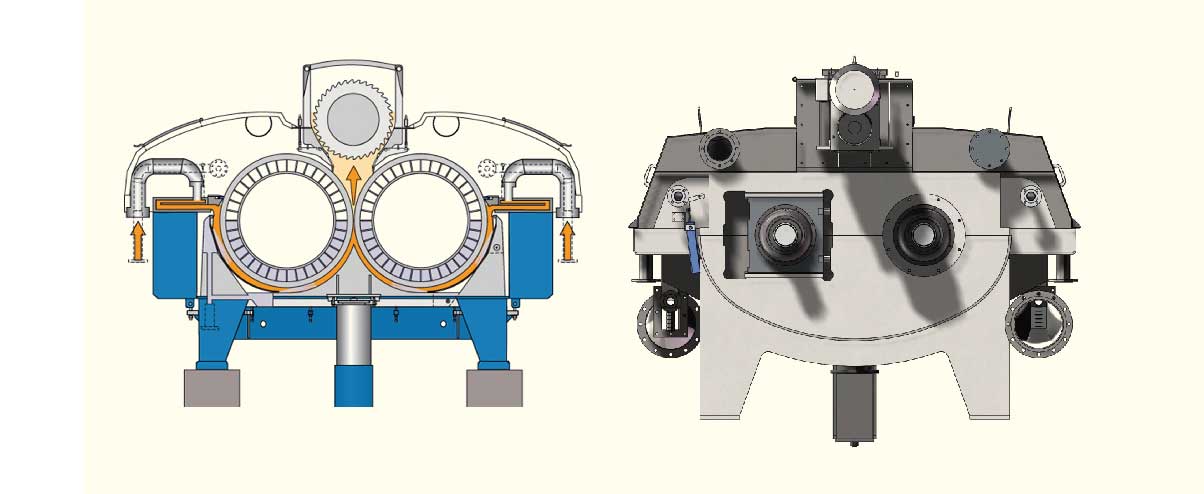

- ZNJ series double mesh pulping machine

- H2627 black liquid filter

Washing system

Paper pulp washing is the process of dissolving the non-fibrous soluble substances in the cooking liquid and adhere to the surface of the fiber by water or dilute waste liquid, and separating them from the fiber, to obtain clean paper pulp. The paper pulp washing can be divided into coarse washing and fine washing.

The purpose of washing

The paper pulp was separated from the black liquor to wash out and purify the paper pulp which was produced by the reaction of alkali lignin in the cooking process, so as to facilitate the selection and bleaching of the paper pulp. At the same time, the paper pulp was washed sufficiently and the cooking waste liquor with high concentration and temperature was extracted and sent to the wastewater treatment for the recovery of organic or inorganic substances from the waste liquor in the recovery process of acid and alkali.

Make the paper pulp suitable for the next processing.

Washing principle

Unwashed pulp, Most of the waste liquid exists in the flow space between fiber (about 70-80% of the total liquid), some in the inner channel of fiber cell (15-20% of the total fluid), only a small part in the pore of fiber wall (about 5% of the total liquid). Therefore, pulp washing is actually a process of filtration and diffusion. Filtration and diffusion are inseparable.

Washing equipment

The washing of paper pulp must adopt a variety of action principles, any washing equipment is in the diffusion, filtration, squeezing one of the main role, the rest of the role as a supplementary, and not simply have one role.

During the washing process, the main washing equipments are: pressure washing machine, screw pulping machine, double roll pulping machine, horizontal belt vacuum washing machine, circular net thickener, side pressure thickener, vacuum washing machine, drop pulping machine, pressure washing machine, a sink, etc.

CNBM representative hot selling products:

- ZNH multi disk vacuum filter

- Vacuum washing machine series

- Drop washing machine series

- Gravity type circular mesh thickener

- H2627 black liquid filter

- ZNJ series double mesh pulping machine

- H2627 black liquid filter

Bleaching system

Pulp is made from the separation of fibers from plants by mechanical or chemical means. The pure cellulose, hemicellulose is white, and the rest of the lignin, starch, pectin, resin and tannins are all colored, and these substances can't be completely removed. Therefore, the paper pulp has a certain color (yellow or brown), that is, this color pulp. Therefore, the bleaching system must be applied to make the pulp have white color, remove some lignin and pigment remaining in the pulp after cooking, and improve the purity of the pulp.

The purpose of bleaching

Bleaching is to use bleach to react with lignin and pigment in pulp so that it can be dissolved into soluble matter or become colorless and kept in pulp so as to achieve the purpose of bleaching pulp. It is impossible to remove lignin in the inner layer of cellulose macromolecular bundles by cooking without seriously destroying cellulose. Bleaching is to further remove lignin and purify paper pulp under mild conditions, so bleaching is the continuation of cooking.

Bleaching principle

Bleaching principle is to mix bleach and size for chemical reaction, reaction products, residue bleach from the paper pulp washing out. Bleaching includes oxidative bleaching and reductive bleaching. Oxidizing bleaching is the process of oxidizing lignin and pigment in pulp to form a simple structure substance. Therefore, oxidized bleached pulp yield is low, but the pulp is of high purity and durability. Reductive bleaching is the conversion of colorless substances to colorless substances by reducing agent and pulp, but they are not dissolved. So bleaching yield is high, but in the air exposure for a long time, and will be oxidized by oxygen in the air to colored substances, so poor durability. This bleaching method is suitable for the bleaching of mechanical pulp and semi-chemical pulp with high lignin content and no need for long-term preservation.

There are four processes in the bleaching process.

- The mixing of pulp and steam.

- The mixing of pulp and chemicals.

- Chemical reaction.

- Remove chemical waste liquid and dissolved lignin from pulp.

The efficiency of these processes has an important effect on the total bleaching process.

Important bleaching equipment

The main equipment of bleaching includes: double channel bleaching machine, tri-channel bleaching machine, bleaching tower and so on. CNBM can provide customers with high quality hot selling products including three-stage bleaching equipment, that is, chlorination tower, alkali tower and so on.

Bleaching equipment in the chlorination section is generally simple upflow chlorination tower. The static head of the tower maintains the pressure of the system to increase the solubility of chlorine. The density of the inlet tower is 3-5%, the bottom of the tower is equipped with propellers, the incoming paper pulp will be evenly distributed to prevent the formation of trench flow. In alkali treatment section, hypochlorite bleaching section usually uses downflow alkaline tower, and the reaction time is controlled by liquid level. A mixer is arranged at the bottom of the tower to provide a turbulent dilution zone to allow a uniform concentration of the effluent (generally 3-5%). Further dilute to the desired concentration before entering the paper pulping machine.

CNBM has rich project experience and first-class manufacturing capability, which can fully meet the manufacturing requirements of various pressure vessels. The company adheres to the enterprise spirit of "science and technology innovation, quality winning, honesty and promise, serving users and establishing a good reputation", and follows the quality policy of "quality first, customer first, self-improvement unceasing, pursuit of excellence". To create products favored by domestic and foreign customers. We will do our best to provide customers at home and abroad with excellent products and quality services. Welcome to contact us!

Leave messages for quotations and solutions. The average response time is up to 24 hours. Your privacy is protected. Check privacy policy here.