super batch cooking production line

- Offering all the paper pulping equipment of the super batch cooking production line as well as the line itself.

- Reducing steam consumption from 2-2.5ton to 0.6-0.8ton for producing 1ton pulp.

- Excellent bleaching properties because of the low Kappa value, high strength, oxygen delignification and other good production conditions.

In 2007, according to the conventional cooking characteristics, our company developed a super batch cooking production line with an annual output of 300,000t. Super batch cooking production line adopts an efficient pulping technology which can save about 60% of cooking steam consumption. Meanwhile, super batch cooking production line can reduce SO2 emission (sulfur dioxide) and soot aggregates from the alkali recovery boiler by 15%. What's more, super batch cooking production line achieves zero emission waste water and reduces the emission of bleaching waste water.

Super batch cooking production line we offer

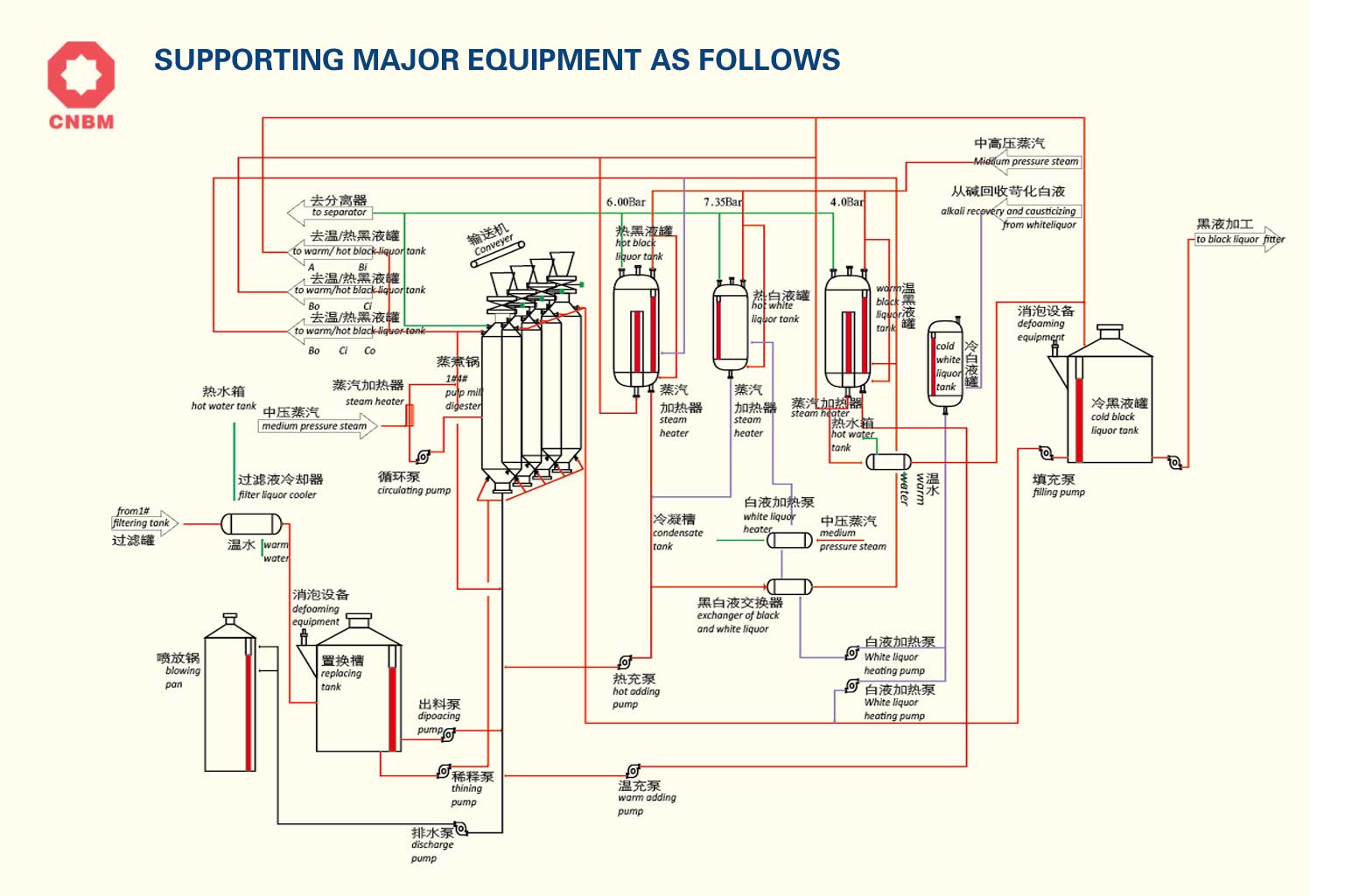

CNBM offers all the paper pulping equipment of the super batch cooking production line as well as the line itself. The Major corollary equipment we need to form a super batch cooking production line is as follows:

-

Gigester

50m3, 75m3, 110m3, 135m3, 175m3, 225m3, 250m3, 400m3 series of digesters with different technologies. The main materials include carbon steel, 316L steel, stainless steel and composite plate , duplex stainless steel structure.

CNBM pulp cooking digester is different from the traditional cooking digester, we added parts including automatic valve, convulsions system, vacuum system, γ rays, blow tank dilution filter, cone tripod, filling nozzle, the steam distributor.According to your requirements, we can customize paper pulp cooking digesters in different size and in different materials. -

Blow Tank

80m3, 150m3, 225m3, 330m3, 500m3, 1050m3 series of blow tanks with different technologies. The main materials include carbon steel, 316L steel, stainless steel and composite plate ,duplex stainless steel structure. According to your requirements, we can customize paper pulp cooking digesters in different size and in different materials. -

Vacuum pulp washer

30m2, 45m2, 60m2, 80m2, 100m2, 120m2 series of vacuum pulp washer with different technologies. The main materials include carbon steel, 316L steel, etc. According to your requirements, we can customize paper pulp cooking digesters in different size and in different materials. -

Replacement tank

Hot black liquor tank, warm black liquor tank, cold black liquor and a variety of heat exchangers with different technologies. The main materials include carbon steel ,composite plate, duplex stainless steel structure. According to your requirements, we can customize paper pulp cooking digesters in different size and in different materials.

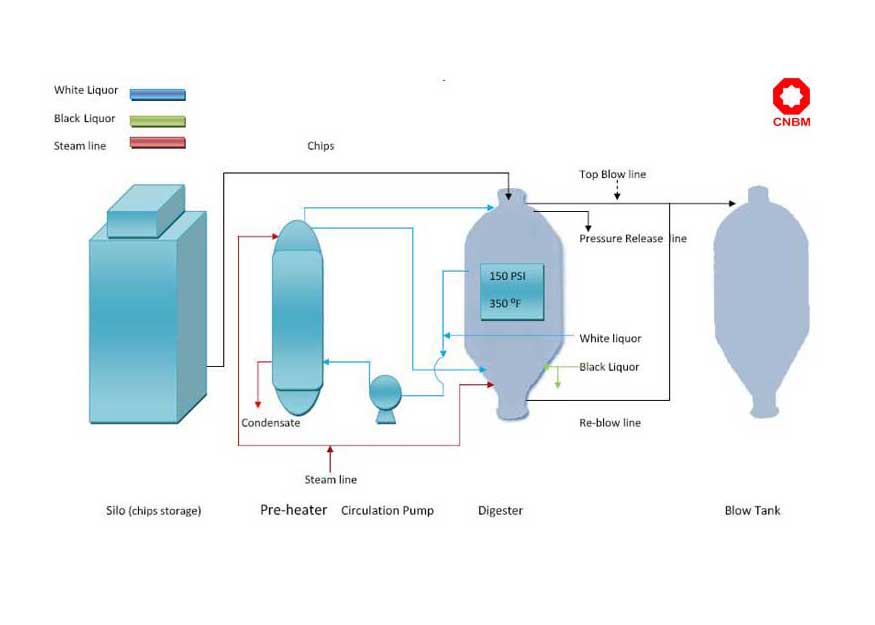

Super batch cooking production line working principal

What makes CNBM super batch cooking production line different is after the impregnation, we use our own way to process the hot black liquid. This method has been patented. It can delignify rapidly under high temperature, and it can lower the hardness of, improve the yield and tearing strength of paper pulp. I'm sorry that I can't offer more details, but we take our independent researches and developments very seriously. If you have interest in our product, please leave a message, our engineer can explain everything you want to know, and customize super batch cooking production line and other paper pulper machines in accordance with your situation.

Pulp cooking digester advantages

- Compared to conventional cooking steam consumption, our equipments can achieve great reduction of energy. Our super batch cooking technology can reduce to 0.6-0.8ton of steam consumption from 2-2.5ton for producing 1ton pulp.

- Oxygen delignification. Low Kappa value. High strength paper.

- Pulp produced by CNBM super batch cooking system has excellent bleaching properties because of the low Kappa value, high strength, oxygen delignification and other good production conditions. Meanwhile, relevant chemical consumption drops down, which can not only reduce the environmental pollution, but also lower the paper cost.

- Because the whole production process is full-automatic and the system reliability is guaranteed, the quality of paper pulp is stable and reliable.

Leave messages for quotations and solutions. The average response time is up to 24 hours. Your privacy is protected. Check privacy policy here.

displacement digesting system

displacement digesting system