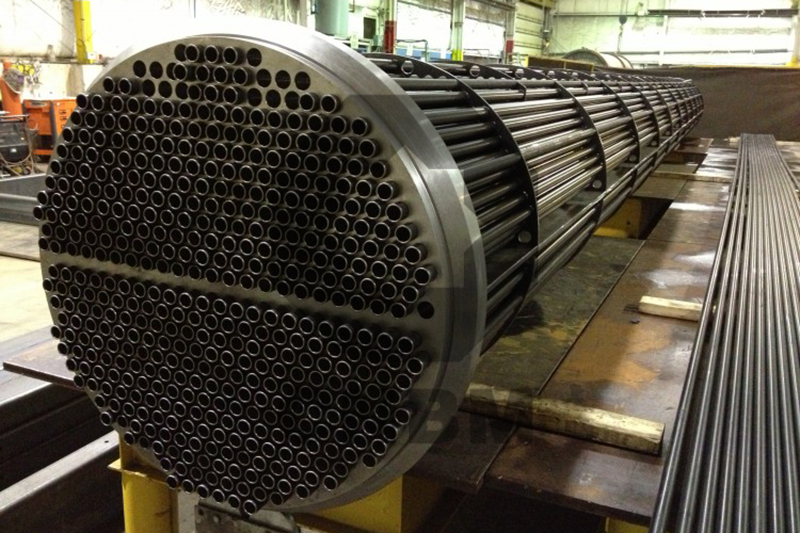

heat exchanger

- All stainless steel production, long service life, up to 20 years or more.

- Heat transfer speed, high temperature resistance (400 ℃), high pressure resistance (2.5 Mpa ).

- The heat transfer coefficient is increased significantly by using nanometer thermal film technology.

Heat exchanger (also known as heat exchangers or heat exchange equipment) are device used to transfer heat from hot fluid to cold fluid to meet the specified technological requirements. It is a kind of industrial application of convection heat transfer and heat conduction.

Heat exchanger we offer

Due to many variables being involved in, selecting optional heat exchanger is challenging. Hand calculations are possible, but many iterations are also typically needed. As such heat exchangers are most often selected via computer programs either by system designers who are typically engineers or by equipment vendors.

To select an appropriate heat exchanger, system designers (or equipment vendors) should firstly consider design limitations for each type of heat exchanger. Though the cost is often more, the primary criteria are more important.

Heat exchanger working principle

- The stainless steel heat exchanger uses the latest eddy current hot film heat transfer technology to increase the heat transfer effect by changing the motion state of the fluid. When the medium passes through the surface of the vortex tube, the hot fluid scour the surface of the tube, which improves the heat transfer efficiency.

- This structure realizes corrosion resistance, high temperature resistance, high pressure resistance and anti-scaling. The fluid channels of other types of heat exchangers are fixed - direction flow patterns , which form a flow around the surface of the heat exchange tube so that the convective heat transfer coefficient is reduced .

- The main characteristic of vortex heat exchanger is the unity of economy and safety.

- Considering the flow relationship between heat transfer tubes, heat transfer tubes and shells, the turbulent flow is not forced by baffle plate, but by natural induction between heat transfer tubes to form alternating vortex flow. And to ensure that the heat transfer pipe does not friction with each other to maintain the due quivering force.

- The rigid and flexible configuration of the heat exchanger is reasonable and it will not collide with each other, which not only overcomes the problem of the damage caused by the collision between the floating coil and the heat exchanger, but also avoids the problem of easy scaling in the common tube and shell heat exchanger.

Heat exchanger advantages

- High efficiency and energy saving.

- All stainless steel production, long service life, up to 20 years or more.

- The laminar flow is changed to turbulent flow, which improves the heat transfer efficiency and reduces the thermal resistance.

- Heat transfer speed, high temperature resistance (400 ℃), high pressure resistance (2.5 Mpa).

- Compact structure, small footprint, light weight, convenient installation, saving construction investment.

- Flexible design, complete specifications, practical pertinence, saving money.

- Wide application conditions, suitable for large pressure, temperature range and many kinds of medium heat exchange.

- Low maintenance cost, easy operation, long cleaning cycle and convenient cleaning.

- The heat transfer coefficient is increased significantly by using nanometer thermal film technology.

- It can be widely used in the fields of thermoelectricity, factory, petrochemical, central heating, food medicine, energy electronics, mechanical light industry and so on.

CNBM offers you world class quality heat exchanger, not only for paper pulp making, but also for other use. Please contact us for details and quotation. Our professional staff will give you a satisfactory reply within a workday.

Leave messages for quotations and solutions. The average response time is up to 24 hours. Your privacy is protected. Check privacy policy here.