pulp cooking digester

- We customize varied size of digesters, including 50M3, 75M3, 110M3, 135M3, 175M3, 225M3, 250M3 and 400M3.

- Our paper pulp cooking digester can reduce the steam consumption from 2-2.5tons to 0.6-0.8ton for per ton pulp.

- High oxygen delignification effectiveness. High strength paper. Low Kappa value. Low relevant chemical consumption.

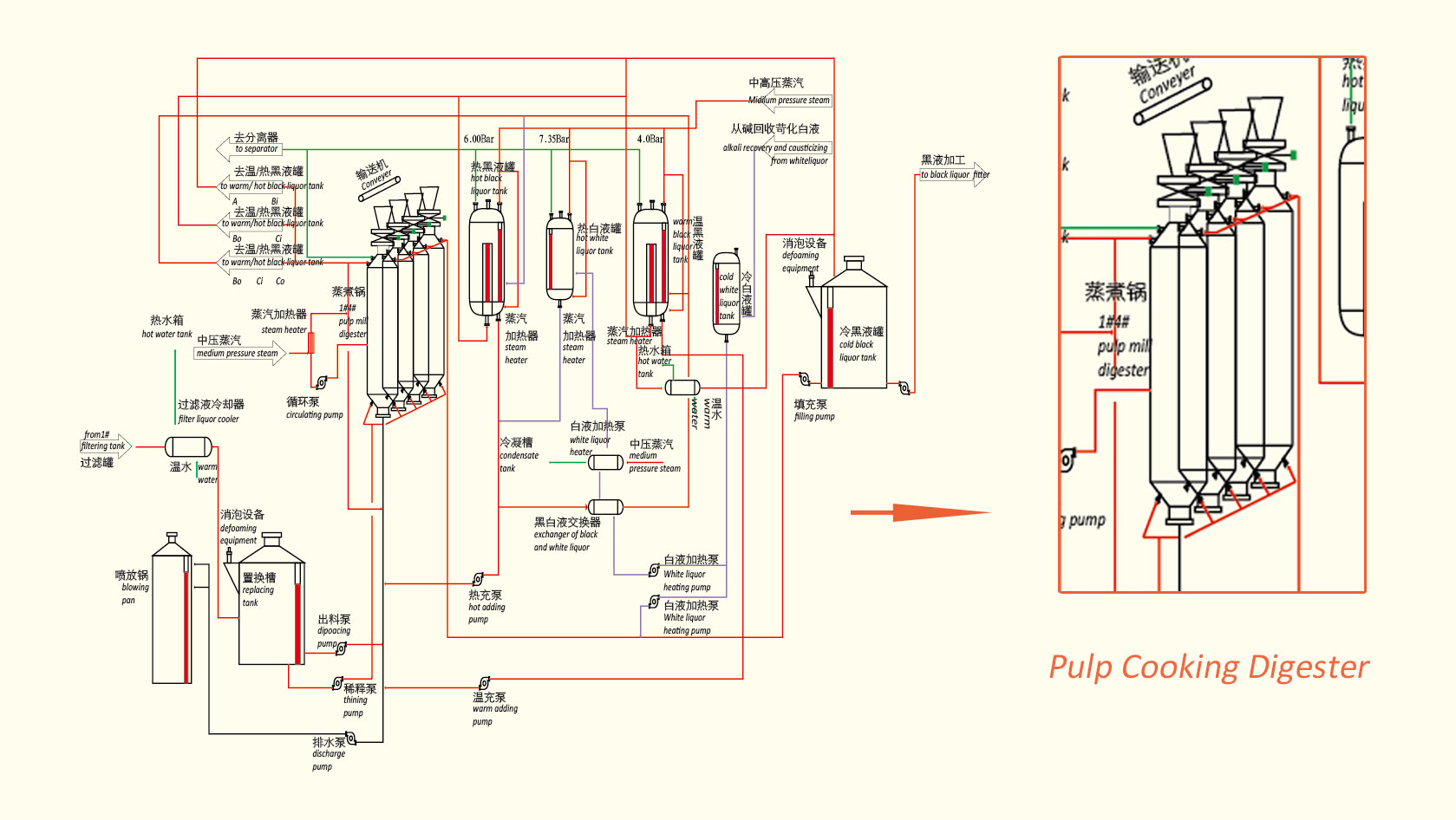

CNBM pulp cooking digester is a kind of batch chemical pulp equipment, mainly used for cooking wood, bamboo, Di, reed and other fiber raw materials. The vertical cooking digester comprises a digester body, a circulation system and a supporting seat. The digester body can be divided to three parts including an upper conical part, a cylindrical part and a lower conical part. Above the upper conical part, there is a feed port. The cylinder part is in the middle of the digester. On its inner wall, there is a cylindrical filter and liquid suction port installed. The lower conical part has a direct steam-through entrances to connect the discharging valve. The circulation system is consist of a tube heater, a circulating pump and a circulating pipe.

Pulp cooking digesters we offer

CNBM adopted the order form production, we arrange production according to the market and customers. We can produce varied size of digesters, including 50M3, 75M3, 110M3, 135M3, 175M3, 225M3, 250M3 and 400M3. Our digesters are mainly used in cooking workshop. The maximum diameter of our paper pulp cooking digester can reach 5.8 meters, the maximum capacity can reach 400 cubic meters.

In view of the differences between the processes of alkaline pulp and acidic pulp, the cooking digester can be made of carbon steel, composite steel or duplex stainless steel. The cooking pot is mainly used for chemical pulp cooking and fiber dissolved steaming operation. Our pulp cooking digester can be used with GLV and other well-known chemical pulp production line equipment. Now, our paper pulp cooking degisters are widely used at both home and abroad.

pulp cooking digester parameters

| MODEL | ZJG1 | ZJG2 | ZJG3 | ZJG4 | ZJG5 | ZJG6 |

|---|---|---|---|---|---|---|

| Effective volume(M3) | 50 | 75 | 110 | 135 | 175 | 225 |

| Diameter(internal) | ¢3000 | ¢3250 | ¢3600 | ¢3600 | ¢4500 | ¢4500 |

| Maximum working pressure(Mpa) | 0.8 | |||||

| Maximum working temperature (℃) | 175 | |||||

corollary quipment technical parameters

| Lye heater | Model | ZJG1-2 | ZJG2-2 | ZJG3-2 | ZJG4-2 | ZJG5-2 | ZJG6-2 |

|---|---|---|---|---|---|---|---|

| SpecM2 | 40 | 65 | 90 | 110 | 140 | 190 | |

| Lye circulation pump | Model | ZBY21 | ZBY22 | ZBY24 | ZBY24 | ZBY24 | ZBY24 |

| Spec | ¢200 | ¢250 | ¢300 | ¢300 | ¢300 | ¢300 | |

| Dumping ball valve | Model | Q647Y-16P | Q647Y-16P | Q647Y-16P | Q647Y-16P | Q647Y-16P | Q647Y-16P |

| Spec | ¢200 | ¢200 | ¢200 | ¢200 | ¢300 | ¢300 | |

| Automatic pot cover | ¢770 | ||||||

| Blow tank | Model | ZJP2 | ZJP3 | ZJP4 | ZJP5 | ZJP6 | ZJP7 |

| Spec M3 | 150 | 225 | 330 | 400 | 500 | 800 | |

| Diameter (internal) | ¢5000 | ¢5600 | ¢6500 | ¢7000 | ¢7000 | ¢7000 | |

| Max working pressure (Mpa) | 0.25 | ||||||

| Max working temperature(℃) | 175 | ||||||

Pulp cooking digester working principal

- Paper pulp cooking digester is mainly used to process wood, bamboo and other raw materials for making paper pulp. The moisture content of raw materials should be less than 15%, the ash content should be less than 2%-3%, the cellulose content should be kept within 50% -55%, the lignin content should be kept within 22% -25%, the silicon content should be less than 3%.

- To cook paper pulp, first, the material should be cut into thin slices (25MM-30MM) by wood chipper or other machines. Then through the conveyor belt, the slices will be put into the cooking digester which is filled with coolant and steam. The cooking time is determined by the pulping requirements (pulp yield and hardness) and generally, it will last for 5.5-6 hours.

- The cooking temperature is about 160 ℃ -175 ℃. The heating process is mainly involved in the effective indirect heating tube heater area from the center of the liquid flow through the tube from top to bottom heating and transportation, and then hourly heating cycle 8-12 times. In the meantime, steam enters through the vents at the bottom and acts as an adjunct to heating.

- During the pulp cooking process, the exhausting gas is vented through the upper vents to reduce the pressure build-up caused by the air inside the digester body to ensure the consistency of the cooking pulp and to improve the quality of the pulp.

- When the cooking process is completed, the paper pulp just cooked is under great pressure. Using the discharging valve to leave the pot into the unloading tank, then the paper pulp can be stored temporarily.

Pulp cooking digester advantages

- Compared to the conventional cooking process, our pulp cooking equipment needs less steam, in other word, lower steam consumption. Our paper pulp cooking digester can reduce the steam consumption from 2-2.5tons to 0.6-0.8ton for per ton pulp.

- High oxygen delignification effectiveness. Low Kappa value. High strength paper.

- Excellent bleaching properties. Good production conditions. Low relevant chemical consumption, which not only reduces environmental pollution, but also lowers the cost.

- The whole production process is full-automatic, thus the system reliability is greatly improved, and the pulp quality is stable and reliable. Fully automatic control for the production line, advanced reliability of cooking system, stable and excellent pulp quality.

Leave messages for quotations and solutions. The average response time is up to 24 hours. Your privacy is protected. Check privacy policy here.